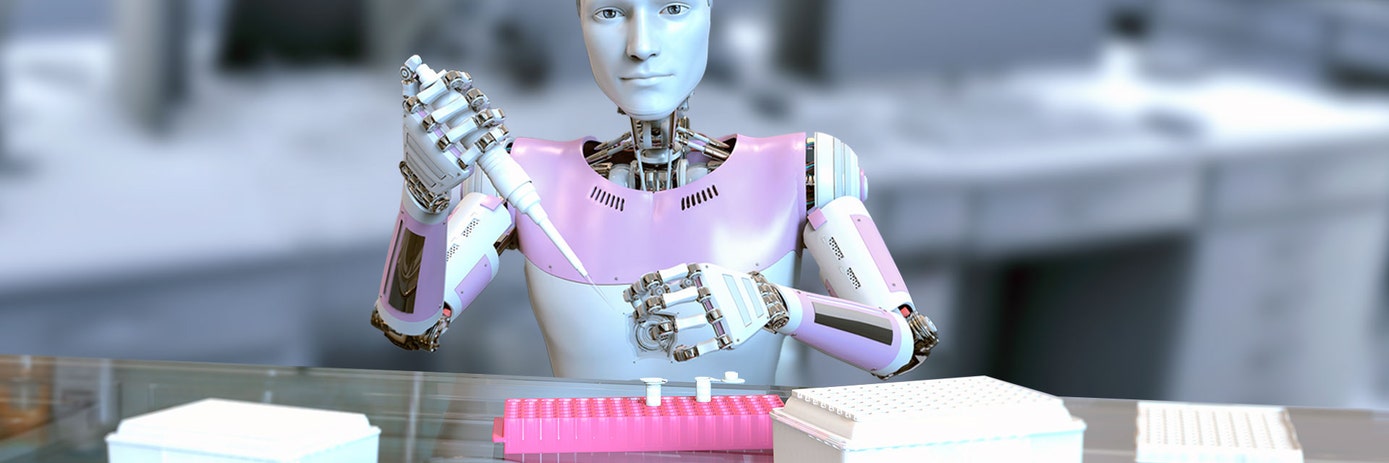

For decades, liquid handling was recognized as a key barrier to increasing experimental throughput, particularly in the life sciences. Automated liquid handling systems have effectively reduced this barrier, unlocking the door to standardized experimentation with high-throughput capacity with consistent and robust data at varying levels of scale. As the applications for these systems have continued to grow, so too has the need for instruments that provide solutions rather than create further barriers.

The benefits of automated liquid handling

Automating processes and workflows in the sciences has many benefits including:

- Increasing experimental scale and throughput

- Improving reliability, repeatability, and efficiency

- Decreasing the amounts of reagents and solvents needed

- Reducing hands-on time while increasing data generation

- Audit and data records and reports

Research requiring liquid handling has particularly benefited from automated systems, as manual pipetting limits experimental scale and efficiency. Furthermore, human error coupled with differences in technique between individuals leads to deficiencies in consistency and repeatability. With automated liquid handling, protocols can be standardized and their utilities and impacts expanded.

Automated liquid handling workstations are key components of workflows within industry, academia, and healthcare, and enable users to generate large datasets while saving time and resources. Their applications range from high-throughput screening to blood fractionation to NGS library preparation, and they have played key roles in ushering in the current era of “big science”. While their reformatting function is straightforward – transfer a set amount of liquid from one type of container to another – these systems must be far more than pipetting robots in order to benefit users.

Researchers need more than a pipetting robot

The value of an automated liquid handler is not achieved simply through automated pipetting. These instruments are the attentive integration of multiple components that require advanced robotics, robust software to plan, coordinate, and customize experimental protocols, and thoughtful design to accommodate different workflows, account for space limitations, and account for the use and disposal of consumables. Additionally, some users need systems that comply with the requirements of regulatory bodies, while all users benefit from instruments that are accompanied by knowledgeable service and support.

Deficiencies in any of these areas can have significant negative impacts. Beyond the many functional and design considerations necessary for a standalone instrument, automated liquid handlers must also function as one part, albeit a key one, of the end-to-end systems required for automated and high-throughput experimentation. They must have the necessary hardware, software, and design elements to enable integration and precise coordination with other instruments within the workflow.

Utility is expanded through customizable and adaptable design and support

While the efficiency and throughput capacity of automated liquid handlers is fully established, users cannot truly benefit from these systems unless they offer flexible and adaptable solutions. Not all users need top-of-the-line capabilities, and different users have different physical space constrictions. Furthermore, automated liquid handlers do not necessarily represent immediate solutions for researchers; protocols and workflows must be programmed and tested, chemical reaction processes developed and validated, and appropriate QC performed.

For example, the preparation of NGS libraries relies heavily upon automated liquid handlers, but simply purchasing one does not provide a solution. Users may need to program the instrument for their workflow, develop and test chemistry, validate sequencing, and perform QC. It can take months for users to adapt or design a system to their specific needs after receiving it, representing a loss of time and resources. Choosing a vendor like Revvity that already has sequenced libraries for the NGS kit of interest can save months of implementation time for the user.

In the video below, John Fink, General Manager of Automated Liquid Handling at Revvity, discusses the capabilities of their automated liquid handling systems with a particular focus on applications for next-generation sequencing.

Automated liquid handling systems from Revvity come with solutions

Understanding that there is no one-size-fits-all automated liquid handler, Revvity focuses on providing solutions rather than products. Their suite of automated liquid handling systems provides access to application-specific benchtop workstations as well as complex customized workflows, all equipped with powerful software which enables scientific exploration while providing flexible monitoring capabilities such as video-recording of errors, deck verification, and remote monitoring. Additionally, their liquid handlers have over 120 vendor-qualified methods for NGS kits, meaning that researchers can begin experimentation in as little time as one week. With over 40 years of experience in providing automated liquid handling solutions, Revvity has the expertise needed to support and enable their customers.